Sustainability

Environmental

and Climate Impact

Consideration

for the planet

We are moving towards future-proofing Eton in how we design, produce, ship, package, and distribute our products. To address the environmental impact of our products, we prioritize material topics such as climate impact, circularity, more sustainable materials, pollution in supply chain, chemical management, and responsible water usage throughout our supply chain.

Science Based

Target Initiative

The Science Based Targets initiative (SBTi) has approved Eton Group’s science-based emission reduction targets for its own operations (Scope 1 and 2) as well as its value chain (Scope 3). In addition, the SBTi has validated Eton’s Net Zero targets for Scope 1, 2, and 3. This validation confirms that our climate strategy and targets are scientifically robust and aligned with the Paris Agreement.

The SBTi defines and promotes best practices in science-based target setting, providing a clear framework for organizations to align their emissions reduction strategies with global climate goals. The initiative develops standards, tools, and guidance that enable companies to set greenhouse gas (GHG) reduction targets consistent with limiting global temperature rise and achieving net-zero emissions by 2050 at the latest.

The SBTi is a collaboration between CDP, the United Nations Global Compact, the World Resources Institute (WRI), and the World Wide Fund for Nature (WWF). It operates as a charity, with a subsidiary that independently assesses company targets.

Eton’s near-term targets (validated by SBTi)

- Reduce absolute Scope 1 and 2 GHG emissions by 91.6% by 2030, from a 2019 baseline.

- Reduce absolute Scope 3 GHG emissions by 27.5% by 2030, from a 2019 baseline.

- Eton’s long-term Net Zero targets

- Maintain a minimum 91.6% reduction in Scope 1 and 2 emissions from 2030 through 2050, based on a 2019 baseline.

- Reduce absolute Scope 3 GHG emissions by 90% by 2050, from a 2019 baseline.

These targets demonstrate our commitment to aligning with climate science and contributing to global efforts to limit warming to 1.5°C. The SBTi’s validation marks a milestone in our progress, reinforcing our dedication to accelerating climate action while growing our business profitably and sustainably.

Climate

Action

Climate Action is one of our prioritized SDG goals. We are committed to reducing our emissions and minimizing our impact on ecosystem services, and we acknowledge the need to transition from conventional materials and increase the use of preferred materials.

We align with the Paris Agreement, with our emission reduction targets validated by SBTi, and we commit to reach science-based net-zero target by 2050. Eton Group AB commits to maintain at least a 91.6% absolute reduction in Scope 1 and 2 GHG emissions, and to reduce absolute Scope 3 GHG emissions by 90% by 2050, from a 2019 base year. These target boundaries include land-related emissions and removals from bioenergy feedstocks.

Focus

Areas

In our quest to reduce emissions and minimize our impact on ecosystem services, we’re committed to transition from conventional to sustainable materials. We also focus on energy efficiency and on adopting renewable energy sources for Scope 1–3 emissions. Transportation is our third focus area, and we are currently exploring alternatives such as sea and train freight and working on future distribution solutions.

Climate

Impact

The Science Based Targets initiative (SBTi) has validated Eton’s science-based targets, committing us to reduce Scope 1 and Scope 2 GHG emissions by 46% by 2030 from a 2019 base year, and to measure and reduce Scope 3 emissions. As a long-term target, we have committed to reach net zero by 2050.

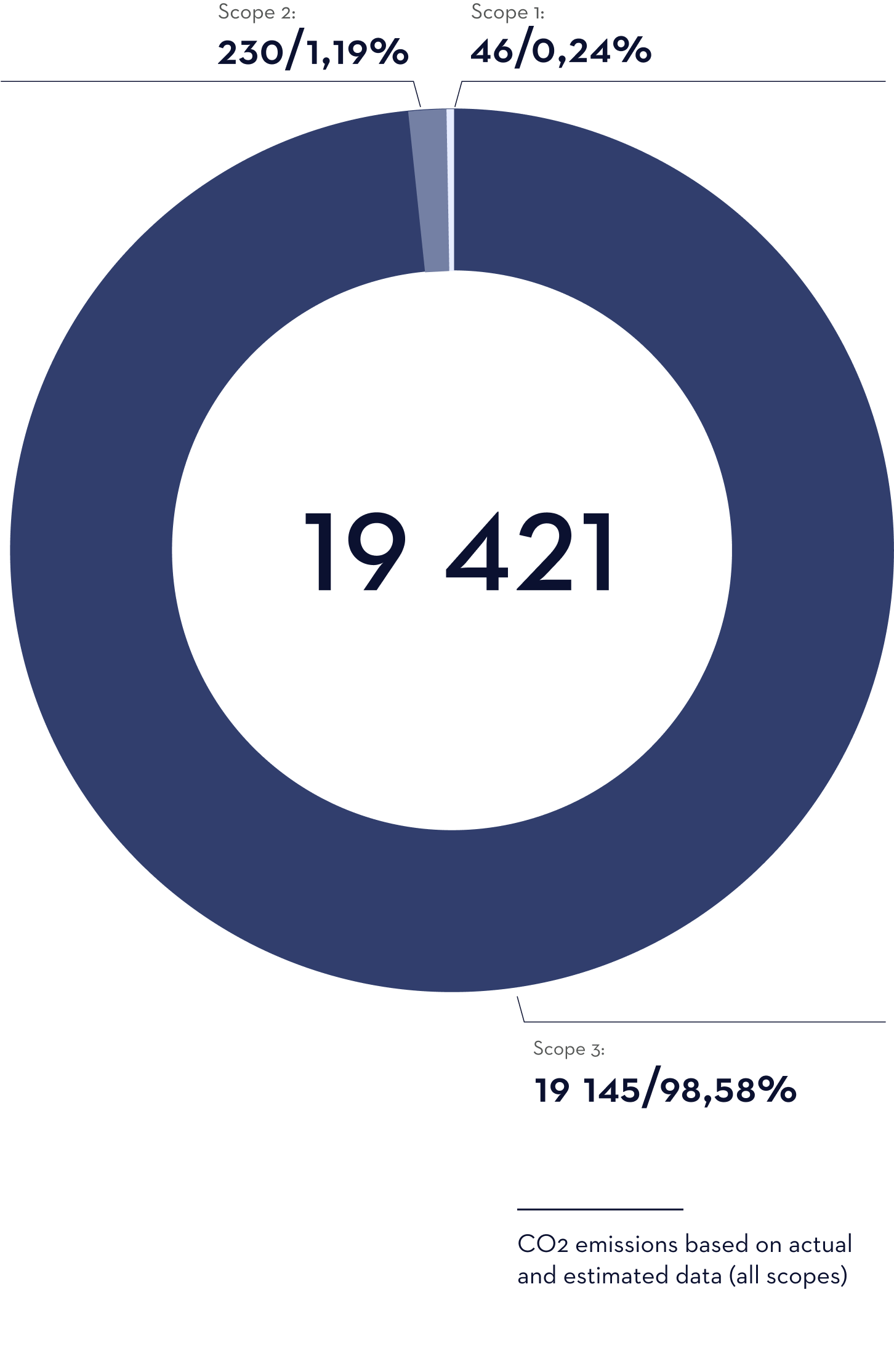

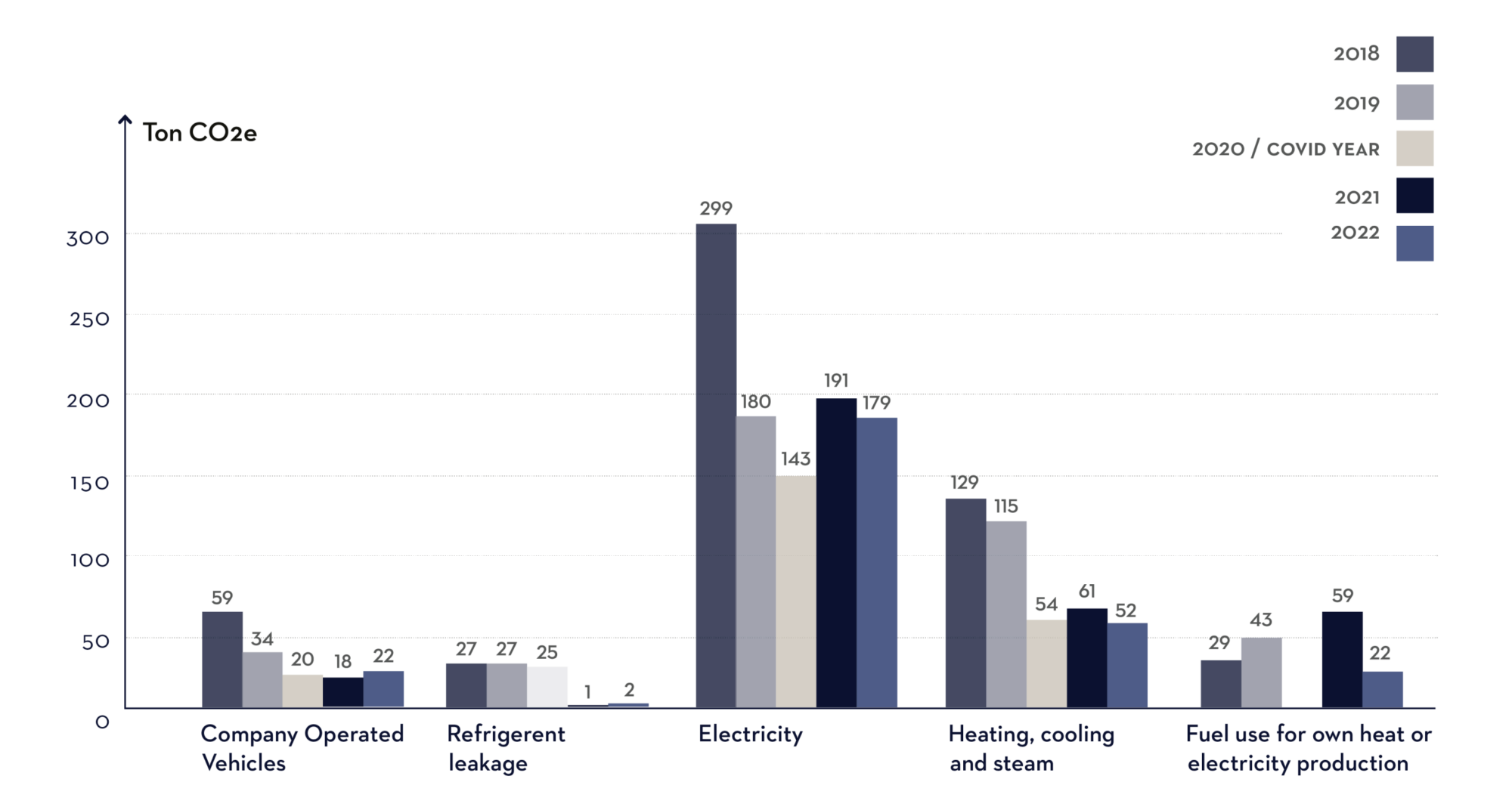

Since 2018, we have been tracking and reporting our Scope 1 and Scope 2 emissions, with 2019 set as the base year. Nearly all of Eton’s emissions, 99.4%, are based on actual data. In the financial year of 2024, our total emissions were 10,242 tons of CO₂e, a 37% reduction compared to 2023.

By consistently measuring, analyzing, and reporting across Scopes 1, 2, and 3, we continue to reduce our climate impact and align our business with science-based targets

Scope 1:

Direct greenhouse emissions that occur from sources that are controlled or owned by an organization.

Scope 2:

Indirect emissions associated with the purchase of electricity, steam, heat, or cooling.

Scope 3:

Activities outside our control but within our value chain. We have identified three major areas for emission reduction: our suppliers’ energy sources and consumption, our fabric choices, and our distribution.

Fig 8. total emissions scope 1 and 2

Materials

Our goal is that all our fabrics will be more sustainable by 2030. We work to combine sustainability with Eton’s quality standards through meticulous sourcing efforts and a focus on materials with lower environmental footprints.

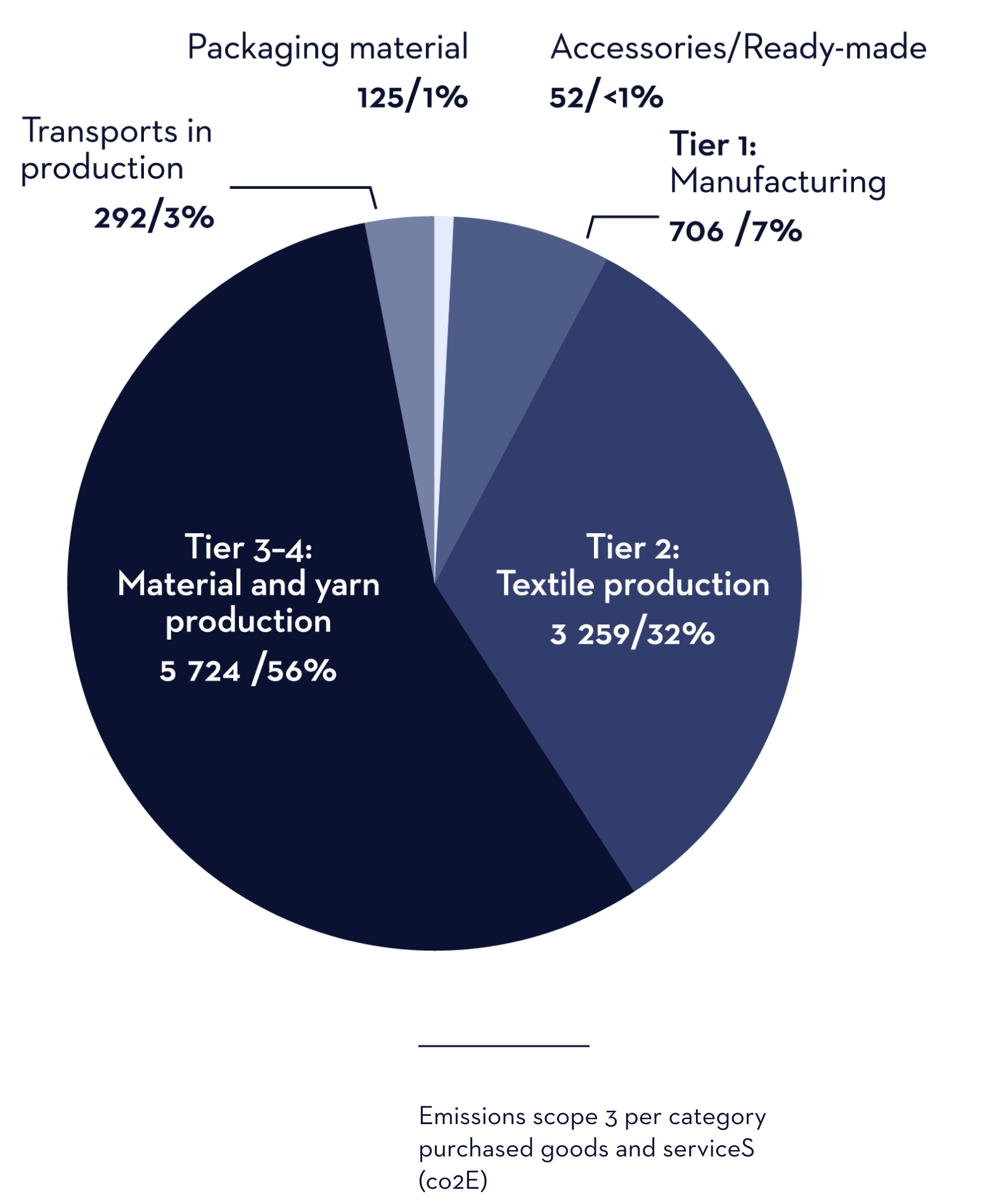

The majority of Eton’s garments are made from cotton. Combined, organic and virgin cotton fibers account for 66% of our total fabric-related emissions—a figure that has decreased thanks to an increased share of organic cotton.

Our assortment team actively works to avoid overstock by sourcing only the necessary amount of fabric and by mapping material choices collection by collection. This strategy reduces excess production and lowers emissions per product. During the year, emissions linked to the amount of purchased fabrics also decreased.

Tier 2:

Emissions from tier 2 (fabric production, weaving, finishing) are almost as significant as those from raw materials and yarn production. By collaborating with suppliers to increase the share of renewable energy used, we can reduce emissions in this tier.

Tier 3 and 4:

Within the production phase, the biggest impact in terms of emissions come from Tier 4 (raw materials) and Tier 3 (yarn and fiber processors, including trims).

Water use

Our goal is to promote sustainable practices and preserve access to clean water for everyone. Since our non-iron finishing process involves chemicals, we use a closed loop system that prevents their release into the environment. We rely heavily on cotton as a material for our products, a commonly used material, which requires a substantial amount of water to produce. In addition, all materials we use require water in its production, in an attempt to measure our water consumption for tier 3–4 we have calculated our water usage based on MSI Higg’s Water scarcity numbers (MSI 2022). None of our Tier 1 and 2 suppliers are active in areas with water scarcity.

Chemicals

At Eton all relevant suppliers sign the Eton Standard, agreeing to our quality standards in three areas: Performance and Quality, Chemical Restrictions, and Flammability. Eton’s Restricted Chemical Requirement and Guide is based on REACH Candidate list for substances of very high concern (SVHC), the Restricted list – Annex XVII of REACH, as well as the OEKO-TEX standard, limiting the use of dangerous and harmful chemicals. This includes legally banned and controlled substances, chemicals known to be harmful to human health but not yet legally restricted, and other parameters for health protection. With a chemical management in place, we look at different aspects of chemical use across the entire value chain: from worker safety in production to customer health and safety.